Welcome to

4T Academy Indiana

Providing students an innovative education experience that couples hands-on learning with on-the-job training, while preparing them for a successful and rewarding career.

Are you interested in 4T Academy Indiana?

We’re currently accepting applications for local partner high schools grades 11 – 12.

Start your path to success today!

Our Partners

Welcome to the 4T

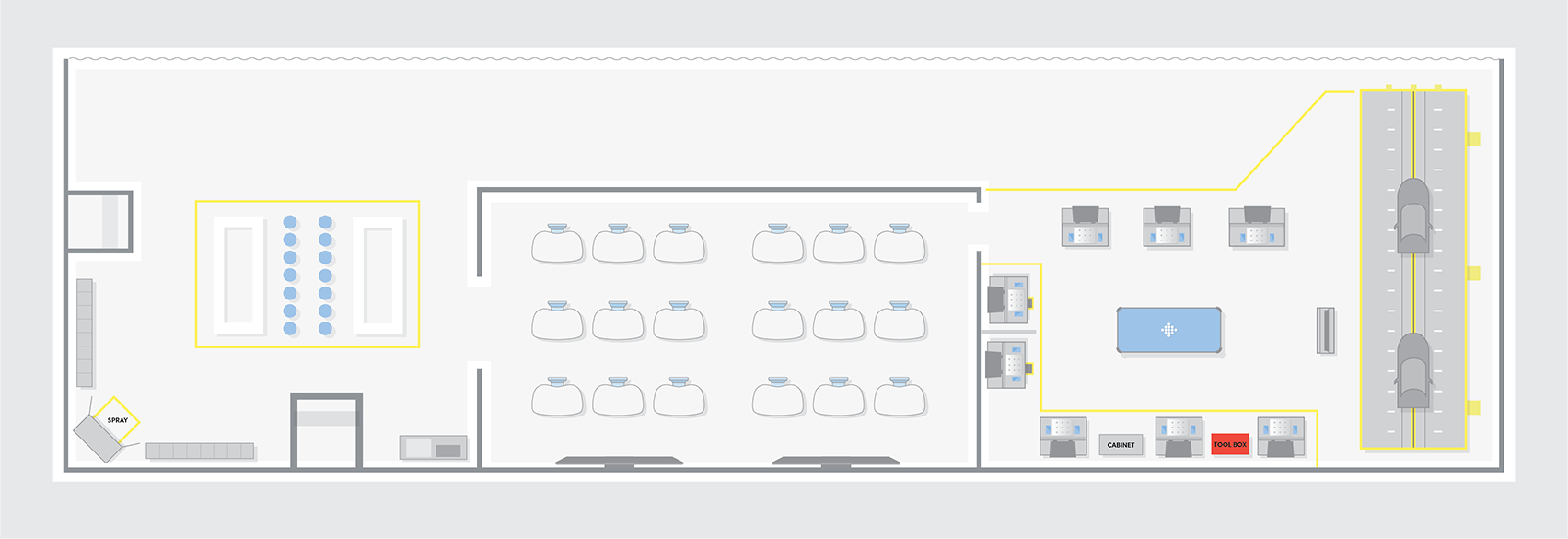

Virtual Tour

Click on the number icons below to see the state-of-the-art4T Academy at Toyota Motor Manufacturing, Indiana.

A HIGH-TECH, HANDS-ON LEARNING EXPERIENCE!

What Students Need To Know...

Get ready to do something big! 4T offers high tech, fast paced, career opportunities in manufacturing, and you get paid to learn. Currently open to juniors and seniors, the 4T Academy allows you to work for the world’s largest vehicle maker and complete your academic coursework. Click below to start your application now!

TMMI HELPS CHANGE POTENTIAL INTO POWER!

What Parents Need To Know...

4T Academy not only gives students a better understanding of career pathways in manufacturing, it’s also a great opportunity for high schoolers who thrive in a technical, hands-on environment. During their last semester in the program, seniors are paid starting at $16 per hour (or higher depending on plant site).

No matter what their plans might be after graduation, this innovative learning experience will provide an opportunity for your student to discover if advanced manufacturing has a role in their future. The tailored curriculum, hands-on participation and paid internship opportunities will help your student see they have career options that are well-paid, fulfilling and close to home.

Testimonials from the Community

FREQUENTLY ASKED QUESTIONS AND MORE

The 4T Hub

The name 4T stands for each of the founding school mascots:

- Tigers (Princeton Community High School)

- Trojans (Wood Memorial High School)

- Titans (Gibson Southern High School)

- Toyota

4T Academy is an incredible option for students who are interested in STEM. This program will give you the opportunity to learn the basic technological skills needed in a manufacturing environment from line workers to managers and engineers.

The goal is to help connect upper-level students in local high schools with career opportunities in advanced manufacturing. By collaborating with local schools, we are creating a workforce solution AND giving students greater exposure to stable, high-paying career options and pathways in the region.

The 4T curriculum includes classes on manufacturing, engineering, computer science, precision machining, industrial automation & robotics, industrial maintenance and environmental sustainability. As a part of the 4T program, students will also participate in hands-on job training at Toyota Motor Manufacturing, Indiana.

Simply fill out and submit the application form linked below.

Toyota Motor Manufacturing Indiana, 4000 Tulip Tree Drive, Princeton, IN